Ultrasonic welding of metal

The Ultrasonic welding uses high-frequency vibration waves to travel to the surfaces of two objects to be welded. Under pressure, the surfaces of the two objects rub against each other to form a fusion between the molecular layers. The main components of a Ultrasonic welding system include an ultrasonic generator, a transducer, an horn, a welding head, a die and a frame.

The Ultrasonic welding uses an ultrasonic generator to convert 5060hz current into 15khz, 20khz, 30khz or 40khz power. The converted high-frequency electrical energy is again converted by the transducer into mechanical motion of the same frequency, which is then transmitted to the welding head by a set of amplitude-changing horn devices. The vibration energy received by the welding head is transferred to the joint of the workpiece to be welded. In this area, the vibration energy is converted into heat energy by friction. Ultrasound can be used not only to weld metals and Thermoplastic, but also to process fabrics and films。

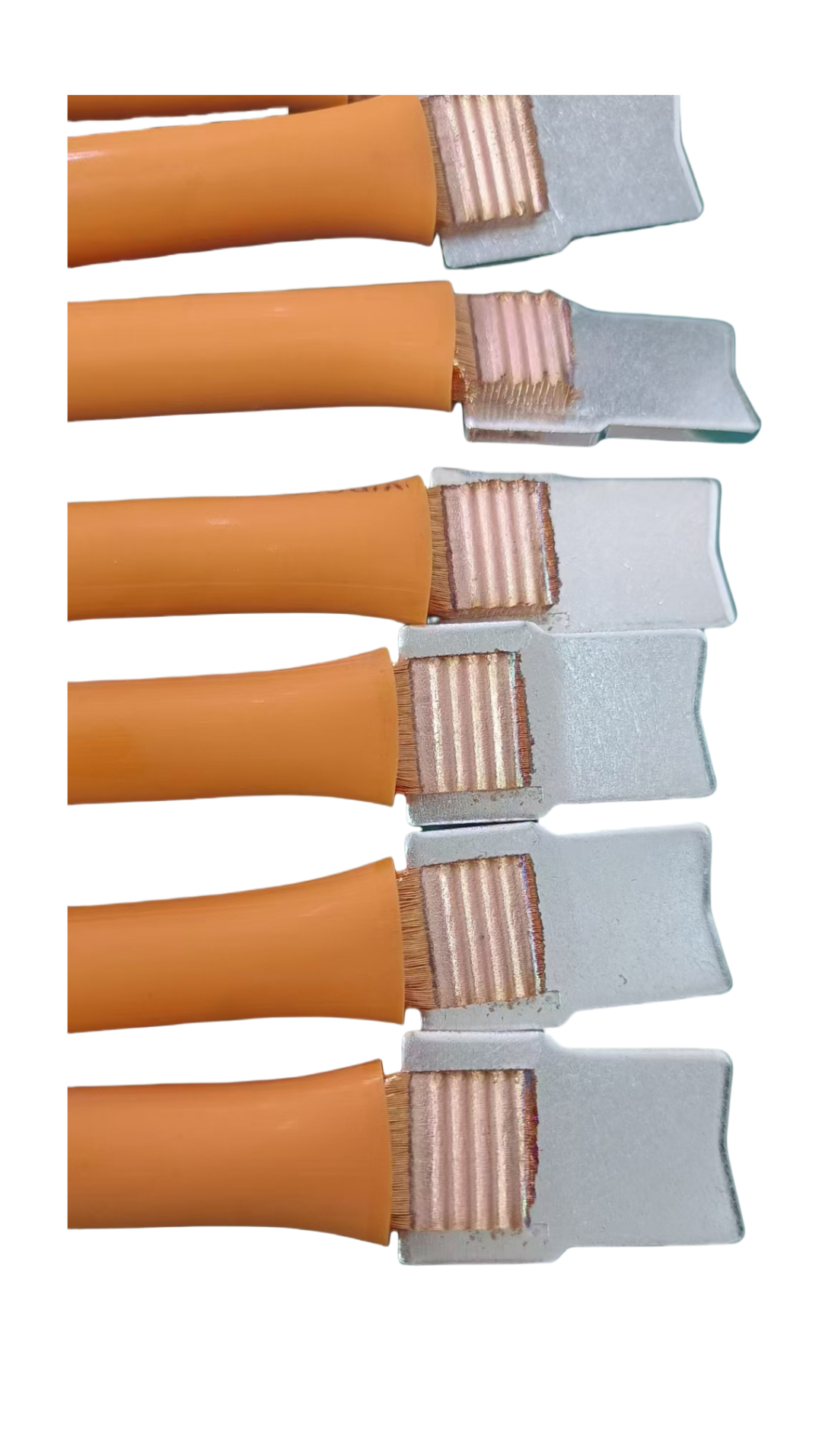

The principle of ultrasonic metal welding is a special method to connect the same metal or different metal by using the mechanical vibration energy of ultrasonic frequency (more than 16 khz) . When the metal is Ultrasonic welding, it neither transmits an electric current to the workpiece nor applies a high-temperature heat source to the workpiece except under static pressure, the frame vibration energy is transformed into the friction work, deformation energy and limited temperature rise between workpieces. Metallurgical bonding between joints is a kind of solid state welding without melting of base metal. Therefore, it effectively overcomes the phenomenon of spatter and oxidation during resistance welding. Ultrasonic metal welders are used for single spot welding, multi-spot welding and short strip welding of thin Non-ferrous metal such as copper, silver, aluminium and nickel. Can be widely used in silicon-controlled lead, fuse chip, electrical leads, lithium battery electrode, electrode lug welding.

SINODA technology is Ultrasonic welding for a wide range of applications with a long prospect of application. For all application markets, ultrasonic welding has the unique advantages of being fast, efficient, clean and robust, won the recognition of all walks of life.